Category: Hampton SKK Gear Motor and Reducers

SKK AF Gearmotor

The SKK type “AF” Gearmotor is the most common type of SKK sold in the US. This is due to several factors.

• Compact Design

• Less Overall Cost

• Minimum Class II Rating

All SKK Gearmotors use 1800RPM motors except for the 37 & 45 output RPM. The 37 & 45 output RPM Gearmotors use a 1200RPM Motor.

The Hampton PT SKK motors have two distinct differences compared to standard motors. A specially designed flange is used to allow the SKK adaptor ring to be bolted to the motor and then attached to the reducer. Also, the motors have tapered shafts to accommodate the SKK pinion gear.

Oil Containment

SKK Gearmotors do not have an oil seal between the motor and the reducer. Hampton PT uses an Oil Slinger Assembly consisting of a cup, disk, and spring washer. These are placed on the motor shaft behind the Pinion gear. As long as oil levels and mounting positions are followed correctly, no oil will leak into the motor when in operation or storage.

Oil Slinger Benefits

• Reduces Maintenance

o Oil Slinger does not have to be changed as frequently as oil seals.

• Helps lubricate the gears and bearings

• Eliminates oil leakage into the motor due to a failed seal

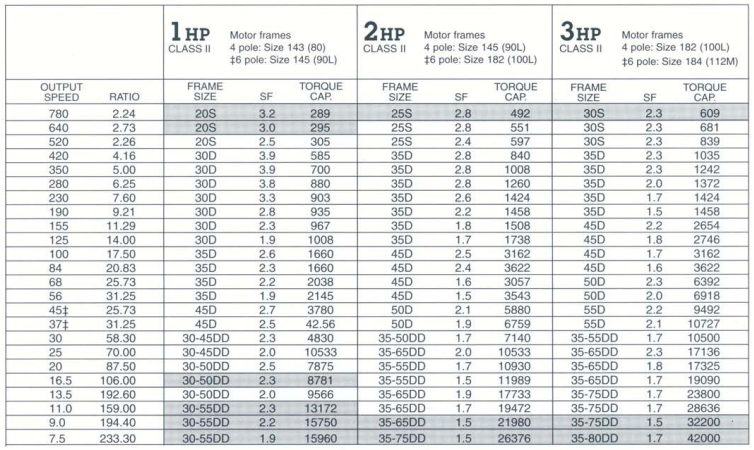

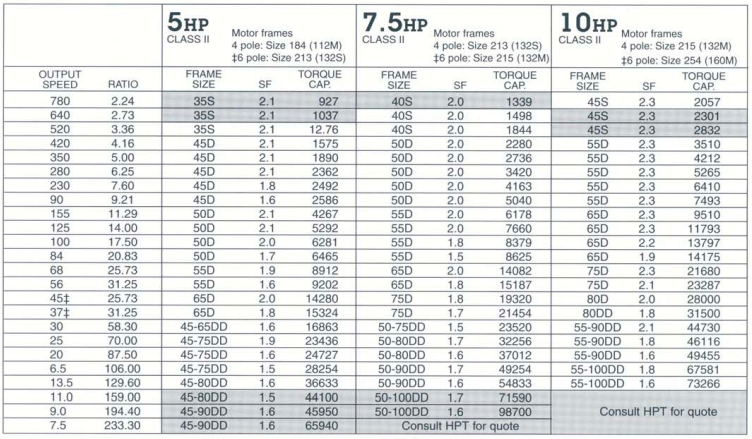

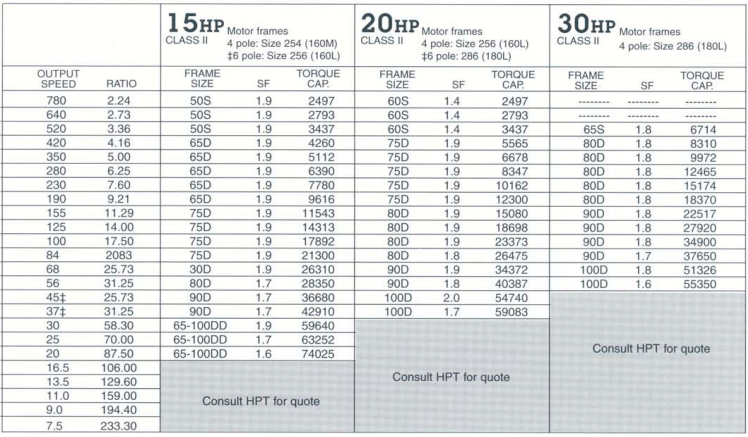

Gear Motor Selection Chart

Units in the white grid stocked for immediate shipment. Units in shaded grid are factor order. Rates are thermal and mechanical and do not need to be de-rated when used according to service factor recommendations. Torque capacities shown are the rating of the gearbox in inch-pounds. Divide torque capacity by the service factor to obtain torque output when the motor is at full load capacity. Symbol ‡ denotes 6 pole motor. Motor sizes in parentheses are for IEC motor sizes supplied prior to 1995.